Aiming at quality and continuity in the die casting industry, Döksan offers ready-to-use solutions to its business partners after melting and casting procedures with up-to-date technologies in its production facility. Being aware of the importance of human resources and high-technology machinery with an industrial background of 40 years, Döksan attributes high importance to training activities

Thanks to its high machinery capacity and experienced staff, Döksan offers thin-wall, intricate-shaped and high-performance parts to our business partners at competitive prices. Producing parts that are considered “difficult to produce” with superior microstructure properties, Döksan offers sustainable solutions with non-porous and first-class mechanical properties

Thanks to its wide range of casting machinery and equipment, Döksan Döküm manufactures different sizes and shapes of cast products and provides solutions to our business partners in a timely manner and at competitive prices.

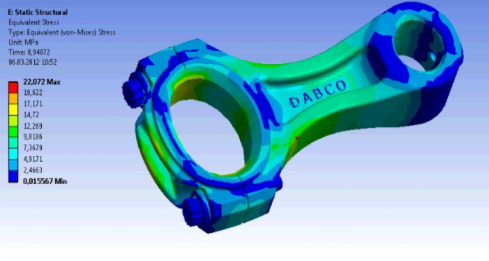

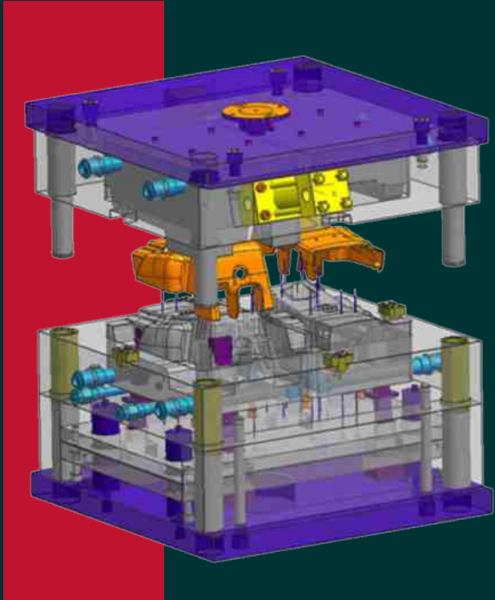

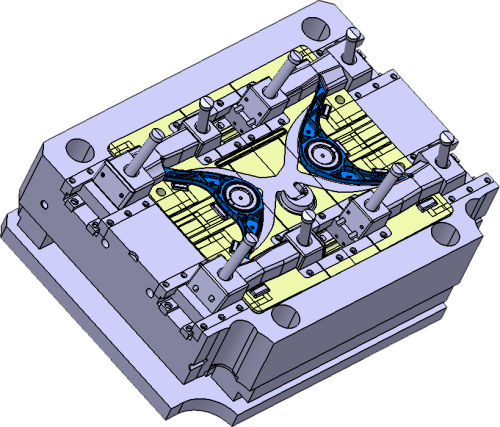

Döksan has the potential to develop products with its experienced staff and software investments, computer aided engineering, Catia V5 for 2D/3D Modelling, Solidworks and simulation programs

With its CAD and simulation program, Döksan is capable of carrying out in-house mould designs and analyses.

Thanks to its integrated facility, Döksan carries out all manufacturing steps from melting to packaging, including machining, test and control processes, on an in-house basis

Just focus on your needs and expectations… We'll take care of the rest.

Always aiming to develop innovative products with superior engineering, Döksan Döküm has been investing for more than 40 years for the necessary technical knowledge and machinery infrastructure so that its customers can access the highest quality of products in a timely manner.

With its machinery and equipment with locking capacity ranging from 400 tons to 1100 tons, Döksan manufactures casting parts up to 12 kilograms for many sectors such as automotive, defence industry, aviation and white goods

Its casting experience and complementary processes that provide added value enable it to offer ready-to-use part solutions to its customers. Optimization of product designs in terms of cost, quality and material properties is achieved through collaborative work with its customers. With the help of simulation and modelling software, it minimizes the mould costs and time spent for the design process and manufactures the highest quality of products in the shortest time.